A plant improvement to make confined spaces safer to work in at Callide Power Station is among the finalists in the annual awards of the Queensland Generators Safety Forum (QGSF).

CS Energy’s Confined Space Isolation Improvement is one of two finalists in the ‘Project or site wide innovation' category at the QGSF 2021 Health and Safety Innovation Awards. The QGSF is an energy industry group that is focused on improving health and safety by fostering collaboration and learning among member companies.

Callide Technical Officer Chris Ross led the project, working with contractor Bob Saunders and the site engineering, mechanical and electrical teams.

They developed a relatively simple and cost-effective solution to provide a safer work environment in Callide B’s electrostatic precipitators during corrective maintenance.

The precipitators help control fly ash emissions from Callide B and undergo regular maintenance to ensure they run efficiently and keep the plant operating within its environmental limits.

As the precipitators require maintenance in between overhauls, CS Energy will typically take one section of the precipitators offline while the others remain in service to support continued electricity generation.

The work areas in precipitators are confined spaces, which require connecting pipework with operating plant to be closed and isolated to provide a safe work environment.

CS Energy’s best practice for workers to enter confined spaces is the ‘double block and bleed method’, which requires at least two isolation points and their connecting vent valve to be locked open to the atmosphere.

Due to the precipitators’ design, one isolation point had been used previously and, in 2019, CS Energy investigated options to improve this isolation.

“Bob suggested an inflatable bag concept he had used at NRG, Gladstone Power Station,” Chris said. “They were using it on a different area of the plant but we thought it had potential for what we were trying to achieve, which was to provide a gas-tight seal that would act as a second block on the inlet and outlet of the precipitator.”

Working with external bag fabrication company Giant Inflatables, a suitable bag was designed, along with anchoring steel work.

In January 2021, the inflatable bag concept was trialled during B station maintenance and proved successful. CS Energy now plans to install the bags on three passes of Unit B1.

Above: The bags prior to installation in the Callide B precipitators earlier this year.

The installation area.

The bags in situ.

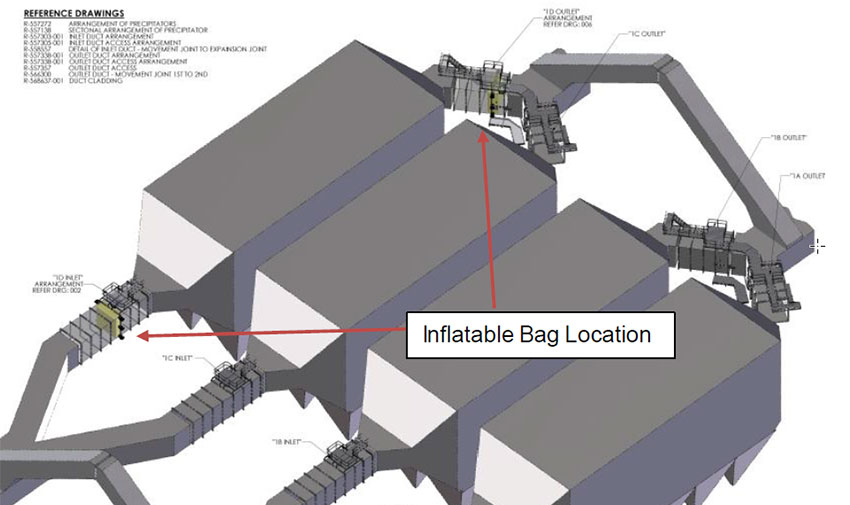

This diagram shows the bag installation points on the inlet and outlet valves of the precipitators.

Chris and Bob will attend the QGSF Awards in Brisbane, which are being held on 29 April and hosted by Origin Energy.

Regardless of the outcome, Chris said he was looking forward to meeting other finalists and learning more about their projects.

“The awards are a good forum for sharing what other generators are doing. We all face very similar challenges and seeing how people come up solutions for them varies from company to company.

“If someone else can benefit from our experience on this project and use it on their plants then that’s a pretty good outcome.”